Solutions » Chemical & Hazardous Goods

Solution for the Chemical Industry & Hazardous Goods Labeling

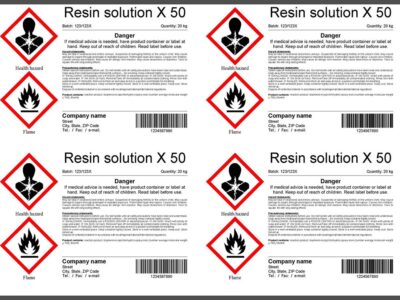

GHS Label Printing in Compliance with Regulations

Field of Application

- Hazardous materials labeling

- Logistics, Pharmaceutics

- BS5609 compliant labeling

- Batch printing with variable data

Highlights at a Glance

- GHS-compliant hazardous materials labeling

- Two color printing to ensure higher impact

- Completely trouble-free paper handling

- Print speed up to 150 mm per second

- SAP®- und AS/400-compatible (through PCL5 + JetCAPS as well as LAN-IPDS)

- Compatible with standard laser printers

Reliable Printing of Hazardous Warning Labels

The interplay of the surface material and adhesive is decisive for the quality and longevity of hazardous goods labels. Liquids, oil, grease, soapsuds, solvents, acids or salt water should not have a negative impact on the labeling or adhesive. This demands the use of advanced materials – and powerful printers capable of handling such materials easily, swiftly and reliably. Thanks to GHS-compliant printing, continuous batch processing and an optimal processing sequence, Microplex logiJET TC8 fulfill such demanding tasks with impressive speed and at a level of quality you can always rely on – even under the most challenging conditions.

- Compliant with GHS / CLP regulations

- BS5609 compliant printing with Microplex materials

- UV-stable, scratch-resistant, water and solvent resistant

Almost Any Application And Connection Can Be Realized

Microplex printers with their Multi Intelligence Controller allow for multiple configurations.

The

Microplex logiJET TC8 is PCL5c-compatible, for example, and can therefore be operated like a laser printer and integrated very easily into production systems such as SAP® R/3.

Adaptations and performance losses thus do not have to be accepted in SAP® applications or when switching from a laser printer to a thermal printer.

- Direct support of SAP® by the HP PCL5c emulation

- No middleware necessary

- No software modification necessary

- Windows® driver supports easy to use handling with all Windows versions

- Many other emulations like PRESCRIBE IIe, Epson ESC/P, CODE-V, …

- Batch printing from roll-to-roll, small foot print – 39 cm x 42 cm

- Fine tuning by „x“- and „y“-adjustment to get perfect register

Robust Printing Unit With Two Colors

The Microplex logiJET TC8 is a thermal transfer printer that is perfect for industrial tasks. It is equipped with two robust printing modules, which can be equipped with any color. Windows applications are supported by a Windows driver optimized for this system for all modern Windows versions. The logiJET TC8 can print on any relevant material like paper, PE, PP, etc. in order to fulfill GHS / CLP regulations and BS5609.

Our Expertise

With the logiJET TC8 you can print material with a width of 100 mm up to 222 mm and almost any length. This ensures that all relevant information can be stored in sufficient size on a label.

This ensures that all relevant information can be stored in sufficient size on a label. Suitable combinations of labels and ribbons are available for a variety of applications. For smaller formats the logiJET TC8 can also be used for multi-labels production very efficiently. A printing unit with two printing modules offers even more advantages:

- Printing on blank material

- Printing black and red in one go

- Reduction of different preprinted labels

- Reduction of storage costs

Individual Color Adjustment in the logiJET TC8 Driver

The logiJET TC8 enables two-color printing, with the first print engine using black by default and the second print engine using red. The second color can be flexibly adjusted via the printer‘s Windows driver. Red is setby default, but a different color can be selected if the document contains a different color specification.

Easy color selection via the driver

The second color can be defined in two ways in the driver menu:

- Directly entering an RGB value

- Selection via the integrated „Color Selection“ menu

Adjust Color Tolerance

The „Accuracy“ setting determines how precisely the color value in the document must match the specified color:

100% Precision → The second printing unit is only activated if the color matches exactly

Default value: 90% → A higher color tolerance allows for small deviations, so the second printing unit is used more often.

Tip:If the desired color is not used in the print, it may be useful to reduce the accuracy.

Multiple Configuration Options

The Microplex printers with their Multi Intelligence Controller have a wide range of configuration options. The printers can thus be individually adapted to the planned application. More than 40 printer languages (emulations) can be selected and configured. In addition to feedback via SNMP and Status-Out, electrical signals can also be used to control and monitor the printers.

- Individual control of the print output via electrical signals with 8 inputs and outputs (GPIO / PLC control)

- Monitoring of printer status and print status via SNMP and Status-Out

- User-friendly configuration & administration via web panel (website)

Downloads

Application Brochure

| Link | Other languages | Size |

|---|---|---|

Application Brochure – Adaptation and Customization Application Brochure – Adaptation and Customization | 1.84 MBytes | |

Application Brochure Hazardous Goods Application Brochure Hazardous Goods | 495 KBytes |

Various Other Downloads

| Link | Other languages | Size |

|---|---|---|

Microplex Thermal Printer Family Microplex Thermal Printer Family | 407 KBytes | |

PDF® Direct Printing with Microplex PDF® Direct Printing with Microplex | 492 KBytes | |

Printing with SAP® & Microplex Printing with SAP® & Microplex | 388 KBytes |