Know How » UHF-RFID Printing and Encoding with Microplex

UHF-RFID Printing and Encoding with Microplex

Maximum reliability for error-free production of UHF RFID-labels

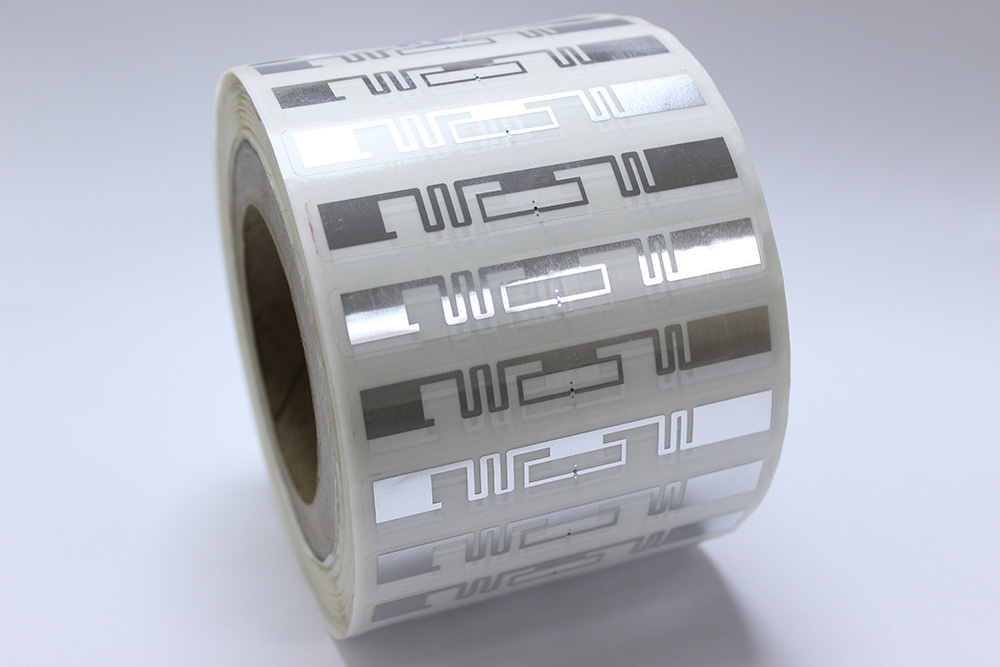

Passive UHF-RFID tags are used when it comes to making internal processes safe and fast. This includes the automatic determination of inventories or the location of means of production.

UHF-RFID labels are also used for cross-company tracking of products along the entire supply chain. The use of radio frequency identification (RFID) contributes to increasing process effectiveness and efficiency, for example within the automotive industry. This applies in particular to the use of passive UHF (Ultra High Frequency) transponders.

Typical applications are the control and tracking of vehicles, components and (reusable) containers. RFID has been used successfully in the automotive industry for many years, primarily in internal, closed cycles, but also in cross-company, open cycles.

Field of Application

- UHF RFID pallet labels

- UHF RFID labels from 15 mm up to 228 mm printing width

- Different materials (Paper, PE, PP, PET, PVC, card board,…)

- Mobile 24V UHF RFID printer

Highlights & Features

- Integrated multi protocol reader 865,6 – 867,6 MHz

- USA (902 – 928 MHz) on request

- EPC C1 G2, ISO 18000-63

- Write/read/verify (invalidation)

- Mostly automatic calibration of the antenna position

- Support of all common tag types with EPC and user memory

Maximum Reliability for Error-free Production Of UHF RFID-Labels

In the wholesale trade passive UHF RFID tags are being used more and more to optimize the warehousing and logistics process. Passive UHF RFID tags have the advantage that they do not require a battery and are therefore very durable.The labels can be easily attached to products and packaging and enable automated collection of information throughout the supply chain process. This means that the labels can be scanned without manual intervention by employees, which speeds up processes and reduces the error rate.

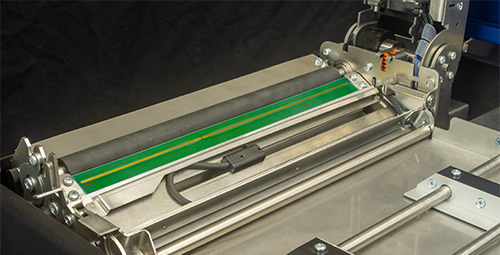

Setting up the Microplex printer on the respective RFID labels is very easy. Depending on the antenna, the antenna positions (depending on the model) are automatically measured. This ensures optimal performance at all times. Faulty or illegible RFID labels cause disruptions, delays and avoidable costs in the chain of use. Therefore, Microplex printers ensure a printout with 100% readable RFID labels.

Printing process of RFID labels: work steps and verifications.

Printing an RFID label involves three steps. After the print data and the data for programming the RFID chip have been loaded into the printer, the printer first checks the correct function of the RFID chip. To do this, the desired content is written to the chip and then read back and compared with the desired content. Only if both match, the visible part of the label is printed.

If the read/write process fails several times, an invalidation is printed on the label. After that, a successful write is attempted with the next label. How often this happens is also configurable. If a successful write is not possible, the printer stops and issues an RFID error message.

Efficient work with Microplex RFID thermal printing systems.

Microplex printers with direct thermal and thermal transfer technology support UHF RFID label widths from 15 mm up to max. 228 mm and antenna distances from 10mm (depending on the model). This means that very small UHF RFID labels as well as labels up to A4 width can be processed. All Microplex UHF-RFID printers are robust, industrial-grade devices with stable metal housings that can withstand the highest loads.

Microplex offers RFID thermal printing systems, both in the thermal transfer and in the thermal direct printing process. In addition, Microplex offers an 8-inch RFID print module, which can be integrated directly into your systems.

UHF-RFID Functionality at a Glance

- Frequency range 865.600-867.600 MHz (ETSI EN 302 208 v 3.1.1)

- RF Power Programmable in 18 Levels (1 dB-steps) from 10 dBm to 27 dBm (from 10 mW to 500 mW)

- Standard protocols EPC C1 G2 / ISO18000-63

- Features read/write/verify (invalidation)

- Registration of the antenna position: automatic (depending on antenna design)

- Checking and invalidating defective RFID labels

On request, the Microplex UHF-RFID printers can also be supplied with a GPIO interface which enables a direct connection to automated production or logistics systems.

A WIFI interface and printer languages for direct connection to AS/400, iSeries servers or SAP environments (IPDS, PCL5, PDF direct printing) are also optionally available.

The Microplex printers with their multi-intelligence controllers have a wide range of configuration options. The printers can be individually adapted to the planned application.

Downloads

| Link | Other languages | Size |

|---|---|---|

Application Brochure – Adaptation and Customization Application Brochure – Adaptation and Customization | 1.74 MBytes | |

UHF-RFID Printing and Encoding with Microplex UHF-RFID Printing and Encoding with Microplex | 350 KBytes |

Our Solutions

Know How