Know How » Interesting Facts about A4 Thermal Printing

Interesting Facts about A4 Thermal Printing

Why 8 inch print width for A5 barcode labels?

The A5 paper format (210mm x 148.5mm), for example, can basically also be printed with a printer that is only 6 inches wide. To do this, the format is transported over the narrow side, i.e. 148.5mm. For many applications, this is also possible without any problems. However, if barcodes are printed and the printing direction of these barcodes is specified via the definition of the labels, various problems arise here with a narrow printer.

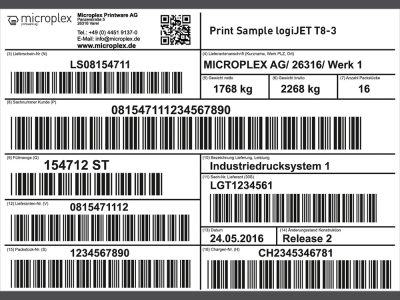

One example clearly shows this: the VDA label. The VDA label is used in the automotive industry, is in A5 format (210×148.5 mm) and was defined by the German Association of the Automotive Industry and looks something like the one shown opposite. On this print sample from a Microplex 8 inch thermal printer, you can see that the barcodes are arranged in the direction of the landscape format. It makes sense in terms of print quality, print head life, and barcode readability to print this label in landscape format.

Your benefits with a Microplex 8 inch / A4 thermal printer:

- If your label design is in the narrow way format:

With Microplex no problem, the printers have a configurable, automatic image rotation, so that the existing data can be printed in wide way format.

Your benefits with a Microplex 8 inch / A4 thermal printer:

- If your data is currently designed for a 203 dpi printer:

Thanks to the intelligent scaling of the print resolution, you can keep your 203 dpi data unchanged and it will print in 300dpi on a Microplex 8 inch printer. This allows all existing applications to be printed without extensive customisation. At the same time, you are prepared for all possible future requirements with the modern printing solutions from Microplex.

Does the printing direction matter? Yes it does!

This is due to the technology of thermal printing, a thermal printer prints using a print head. This print head has a number of heating elements distributed over the entire possible printing width. Each heating element represents a pixel (dot).

If a pixel of a character or a graphic is to be produced on a thermal printer, this heating element is heated. Through this heating, either a dot on thermo sensitive paper (thermal direct printing) or a dot is transferred to the label (thermal transfer printing) with the aid of a thermal transfer film.

Although these heating elements are very small, they nevertheless require a certain time to heat up and to cool again after the printing of the pixel. During this time, the label moves forward in the direction of paper travel under the printhead and is further discoloured.

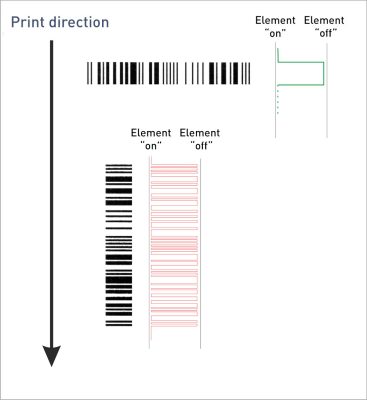

Theoretically, a printed pixel is exactly round in practice it runs slightly in the paper direction as the following graphic illustrates:

When printing bar codes, this property causes the edges in the paper travel direction to become more or less frayed. If a barcode is printed with its bars in the paper feed direction, only the lower ends of the individual bars are slightly blurred. This is irrelevant as far as the size is concerned and decodabilty.

However, if a barcode is printed transversely to the direction of travel, each bar is frayed on one side over its entire length. Since these infractions are located in the gaps between the individual bar code lines, this has a very great influence on the size of the code and hence directly affects the quality of the decode. In the worst case, when such a bar code is no longer decodable, the consequences can range from a slowdown in through put due to key entry or a complete rework to fulfil the customer’s actual requirements. This must be borne in mind as the on costs could be decisive.

The consequences can range from extra work and loss of time due to manual rework to recourse claims from customers. This must be taken into account.

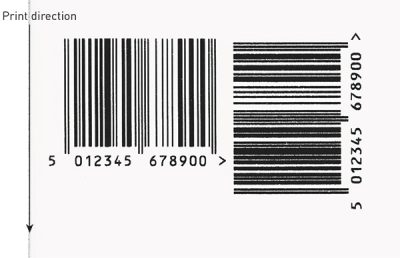

The figure shows the same barcode twice on the same label only the printing direction is rotated by 90 °.

Here it is easy to see that the bar code is altered in its ratio by the so called “ladder print”, i.e. the bars transversely to the direction of travel.

This means that the bars become wider and the gaps become narrower. This changes the quality and legibility of the barcodes only by the direction.

The smaller the bar code is that needs to be printed, the more the effect will be, as the following figure clearly shows:

These barcodes were printed with a width of approx. 0,47 Inch (12mm).

This effect can be alleviated by reduced print speed or larger barcodes, but all of these measures are at the expense of performance. With Microplex A4 thermal printers, you can also print small barcodes with the right orientation and maximum performance and quality.

How is the life of the print heads affected?

Each thermal printhead has a limited life. As a rule, this is about 50,000 meters at thermal transfer printing. This applies to “normal” application. Each time a heating element is switched on and off, the service life is reduced.

The barcode example shows a barcode with 30 bars.

When the printing direction is correct, i.e. the bars are oriented in the direction of paper travel, each heating element involved is switched on and off once for this bar code.

In between, it remains active and prints a continuous line.

This printing behaviour is gentle on the head, especially due to the special print head control (history control) in a Microplex 8 inch thermal printer.

In the other case, i.e. the bars oriented transversely to the direction of paper travel, the corresponding heating elements are switched on and off 30 times for the same barcode!

This means 30 times the stress on the heating elements.

It is obvious that this significantly reduces the service life of a print head.

The following graph illustrates this fact very clearly:

The optimal alignment of the bar codes during printing results in a significantly better utilisation of the maximum possible life of the print heads and thus lowers the printing costs.

More labels at the same printing speed

A further aspect is the print throughput. At the same printing speed, the difference between the print of an A5 label in the wide way format versus the narrow way format is over 40% faster.

When you are printing 100 A5 labels with a 6 inch wide printer, you will produce about 140 labels at the same speed with an 8 inch wide printer over the same time period.

On the other hand, this means that a label printed on an 8 inch wide printer is 40% faster.

This is a tremendous performance enhancement in “just-in-time” applications, which has a positive impact on your overall application.

This assumes, of course, that the controller in the printer that is being used is capable of processing the print data accordingly as quick. With a Microplex A4 thermal printer, this is also the case for complex data.

Microplex thermal printers support most printer emulations in the thermal market. This makes it possible to select the optimum printer language for the highest performance for every application.

An overview of the printer languages and emulations supported by Microplex can be found here: Available Printer Languages (Emulations). Further printer languages (emulations) are possible on request.

Microplex A4 Thermal Printers

Microplex A4 thermal printers (8 inch print width) save time and money by printing complex barcodes cleanly and legibly at all times.

At Microplex you get a product range of A4 thermal printers with a print width of 8 inches. Here you have the choice to find the perfect thermal printer for your application.

Downloads

Application Brochure

| Link | Other languages | Size |

|---|---|---|

Microplex Thermal Printer Family Microplex Thermal Printer Family | 425 KBytes |

Our Solutions

Know How