Solutions » Automotive

Microplex Printers for Automotive Applications

The Right Printer for any Automotive Application

Microplex printers are used in various applications in the automotive industry. The printing technologies used are as diverse as the applications themselves. Both cutsheet laser printers and thermal printers from Microplex are implemented in these applications.

These applications include, for example, the creation of production-accompanying documents, so-called product accompanying documents, the printing of labels that are specifically used in the automotive industry, such as VDA labels, KLT labels, Odette labels, two-colour hazardous goods labels as well as the use of our printers in mobile applications on forklift trucks or mobile workstations.

Both car manufacturers and their suppliers count on our expertise and our adaptability to existing hardware and software systems.

Furthermore, our printers are compatible with various security standards, such as the authentication standard IEEE 802.1X. The simultaneous processing of several printer languages (emulations) on one and the same printer also saves a considerable amount of time and money. Existing data can thus continue to be used and does not have to be “translated” into another printer language.

Cross-technology use also plays a key role in the automotive industry. Depending on the application, laser print data can be output on a thermal printer, thermal print data on a laser printer or line print data on a laser printer without having to make adjustments to the respective application.

You will find more detailed explanations of the respective applications in the following.

Field of Applications

- Storage Slips and Labels

- Production Accompanying Papers

- Two-Color Product Labels

- GTL Labels

- VDA Labels

- Mobile Applications

Highlights / Special Attributes

- Adaptable to customer-specific systems

- Compatible with: IGP, PCL5, IPDS, ZPL II, PDF and more

- Processing multiple printer languages (emulations) simultaneously

- Supports the authentication standard (IEEE 802.1X)

- Optional interfaces (e.g. serial interface) for process-related applications

- Two-color thermal printing (BS5609 compatible)

Storage Slips and Labels, Shipping Documents, GTL and More

In production-accompanying warehousing, the focus is on just-in-time handling. Spare parts must be labelled quickly and reliably.

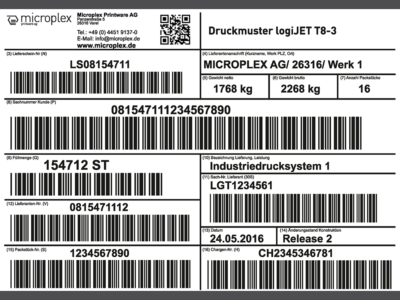

Microplex thermal printers with print widths from 4 inches up to 8 inches are used for printing storage labels. They can output data from different systems in different printer languages (emulations) on one printer. Printer options such as a rewinder, tear-off edge and cutter are also available for effective further processing.

In a specific application, for example, Labelpoint data is extended to print modern 2D barcode identification. The data is generated with the help of specially created software and sent to the printer. Particularly important here is the support of the proprietary communication protocol that provides for feedback of each individual print page (XT-Printcon).

Both the Labelpoint (formerly Markpoint) printer language and the XT-Printcon communication have been adapted to the special customer requirements in the firmware of the printers.

Other applications are PCL5 print data that must be printed on labels (cardboard or foil) in a smudge- and scratch-resistant manner. Feedback to the system takes place for example via the serial interface.

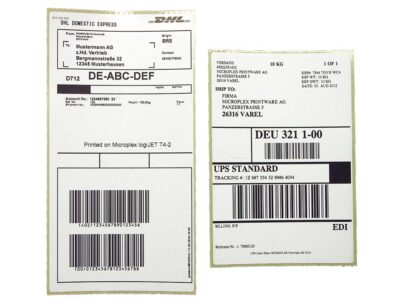

When printing shipping labels, it is important that the barcodes are very easy to read. By using a Microplex printer, you increase your process reliability. Barcodes are always printed with sharp edges and high contrast in the optimum running direction, so that incorrect readings and the associated additional work are avoided.

Benefit from the robust reliability of Microplex printers for smooth multi-shift operation, high availability and short downtimes for material changes.

Shipping labels are often produced using enterprise resource planning systems such as SAP®, which usually output laser printer compatible data (PCL5). All Microplex printers support this printer language (emulation).

No change to the software is necessary. The Microplex printers support barcode printing under PCL5 with the emulation of the so-called JetCAPS module, which provides barcode commands for PCL5.

For VDA and KLT labels (GTL labels or similar), Microplex’s 8-inch printers are used here.

Thanks to the printing width, the 210 mm (A5) wide labels can be processed crosswise.

This means that the barcodes are printed in the ideal orientation (in the print direction) and thus have the best possible print quality. Configuration, monitoring and service (e.g. firmware update) are carried out conveniently via the network using a software tool.

Production Accompanying Papers

Accuracy is required when printing production-related documents. No document may be missing, no document may be printed twice. To ensure this, the Microplex printers have feedback and control interfaces.

Via SNMP or status-out, the software can query information about the printer status as well as the progress of print jobs. Via an electrical GPIO interface, the printer can be controlled with precise timing. This ensures that the right documents are printed at the right time in the right place.

This is where our thermal printers as well as our cut sheet laser printers come into place. For example, the SOLID 52A4 and SOLID 60A3 are used in these applications.

The A4 and A3 cut sheet laser printers SOLID 52A4 and SOLID 60A3 are compatible with the frequently used thermal printer emulations such as IGP-10, Labelpoint, ZPL etc. as well as with line printer emulations such as IBM® Proprinter, Epson ESC, MT-600/MT40 or IBM® terminal protocols such as TN3270 (Telnet). Here, previously used line printers are replaced by fast laser printers with high print quality without having to adapt the application. Any necessary adaptations are realised by the Microplex development department in the firmware of the respective printers.

The scaling of print data originally intended for continuous paper line printers is automatic. Microplex cut sheet printers process the data to fit perfectly onto A4 or A3 formats.

The more than 40 printer languages (emulations) ensure that the print data is printed reliably, barcodes can be read safely and print formats are controlled correctly.

Two-Color Product Labels and Mobile Applications

The logiJET TC8 supports you in printing two-color hazardous warning labels.

The connection to i.e. SAP® is just as easy to implement using PCL5 emulation as printing BS5609 compliant GHS labels.

In the automotive industry, the logiJET TC8 is used in a SAP® environment to create labels for flammable engine fluids in accordance with GHS.

With the logiJET TM8 or logiJET TM4 you get a mobile label printer that offers you maximum flexibility for logistics processes in mobile use.

So you have the choice between the standard stationary use via a 230 volt cable, whereby the printer can be permanently connected to the company network. Or you can use the label printer on the move thanks to the battery supply.

Depending on the application, 12-volt, 24-volt, 36-volt or 48-volt batteries are used.

These printers are used e.g. on forklifts and mobile work vehicles. Here you benefit from the low energy consumption (thermal printing) and the ability of the printer to process several printer languages at the same time.

With one printing system e.g. PCL5 data, IGP data and Kyocera Prescribe data are processed simultaneously.

This means that, despite the complex variety of data, only one printing system is required. Status messages are sent for example via the serial interface, which is still used in various mobile applications in automotive companies.

Multiple Configuration Options

The Microplex printers with their Multi Intelligence Controller have a wide range of configuration options. The printers can be individually adapted to the planned application.

40 printer languages (emulations) can be selected and configured. In addition to feedback via SNMP and Status-Out, electrical signals can also be used to control and monitor the printers.

- Individual control of the print output via electrical signals with 8 inputs and outputs (GPIO / PLC control)

- Monitoring of the printer status and print status via SNMP and Status-Out

- Individual feedback via the data channel (Status-Out)

- User-friendly configuration via web panel (website, IP-Admin)

Customized Firmware Adaptations

If the wide range of configuration options is ever insufficient, we guarantee individual and customised adaptation to the application requirements through our in-house product development and product support. Thanks to short communication channels and close cooperation with our customers and partners, our printers can thus be optimally adapted to the application.

- Individual electrical signals (GPIO / PLC control)

- Hardware adaptations of the printing systems

- Emulation adjustments to support the data streams

- Adjustments of the status messages (Status-Out)

Downloads

Application Brochures & Spotlights

| Link | Other languages | Size |

|---|---|---|

Application Brochure – Adaptation and Customization Application Brochure – Adaptation and Customization | 1.74 MBytes | |

Application Brochure Automotive Application Brochure Automotive | 543 KBytes | |

Application Spotlight Automotive Application Spotlight Automotive | 2.01 MBytes | |

Application-Spotlight Automotive Returns Handling Application-Spotlight Automotive Returns Handling | 193 KBytes |

Various Other Downloads

| Link | Other languages | Size |

|---|---|---|

Direct Printing of IPDS Data Direct Printing of IPDS Data | 479 KBytes | |

Microplex Thermal Printer Family Microplex Thermal Printer Family | 425 KBytes | |

PDF® Direct Printing with Microplex PDF® Direct Printing with Microplex | 497 KBytes | |

Printing with SAP® & Microplex Printing with SAP® & Microplex | 392 KBytes |